Why Regular Calibration of Thread Gages Is Critical for Houston Manufacturers

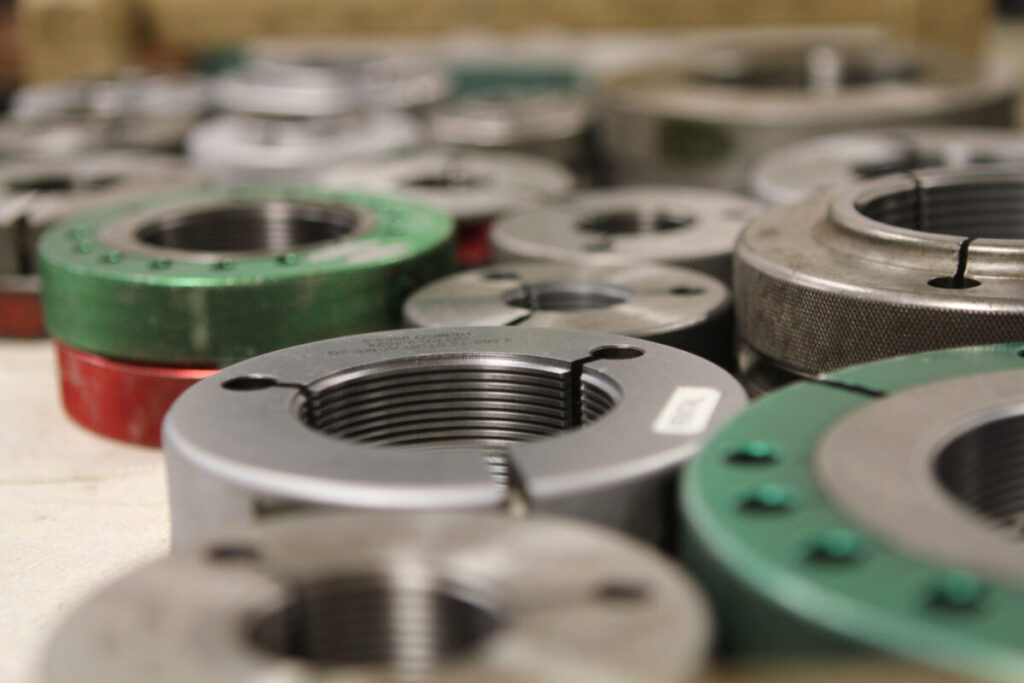

In Houston’s highly competitive manufacturing landscape—spanning oil and gas, aerospace, and automotive industries—product quality can make or break a company’s reputation. One often-overlooked yet critical aspect of maintaining Houston manufacturing quality is thread gage calibration. Without regularly calibrated thread gages, manufacturers risk costly production errors, compromised safety, and diminished customer satisfaction. In this blog post, we’ll explore why routine calibration of thread gages is essential and how Southwest Calibration Service in Stafford, Texas, stands out as a trusted partner for accurate threading and dependable Houston calibration services.

The Importance of Thread Gage Calibration

- Ensuring Consistency and Reliability

In fast-paced manufacturing environments, especially in oil and gas or aerospace operations, every component must fit together with absolute precision. Even minor deviations in thread measurements can lead to faulty parts that fail at critical moments. Thread gage calibration ensures that all threaded connections meet exact specifications, thereby improving overall manufacturing consistency. - Reducing Production Errors and Downtime

A single uncalibrated gage can introduce an error that cascades throughout the production process. The result? Unexpected rework or scrapped parts, which translates to delays and increased costs. Routine Stafford calibration services help you catch these discrepancies early, reducing the likelihood of extensive rework and saving your team both time and money. - Meeting Industry Standards and Regulations

Industries such as oil and gas, aerospace, and automotive are held to stringent safety and quality standards. In many cases, compliance regulations require regular thread gage calibration. Failing to meet these standards can result in hefty fines, legal consequences, or even a damaged brand reputation.

Risks of Using Uncalibrated Thread Gages

- Faulty Threading and Part Failures

Uncalibrated thread gages may show acceptable tolerance levels even when the actual threads are out of spec. This could lead to improperly threaded components that fail under stress or do not form the required seal—an especially critical concern in high-pressure oil and gas applications. - Increased Production Costs

When threads are out of tolerance, production managers often face last-minute scrambles to fix defects, expedite parts, or reorder supplies. All of these unplanned expenses can quickly add up. Regular calibration minimizes the likelihood of these financial pitfalls. - Loss of Customer Trust

As word spreads about quality issues, a manufacturer’s reputation can take a significant hit. By contrast, demonstrating a commitment to accurate threading through routine calibration not only ensures consistent quality but also fosters trust and loyalty among clients.

Houston’s Key Industries Rely on Accurate Thread Measurements

- Oil & Gas: Drilling equipment and pipeline components must be able to handle extreme pressures. Mis-threaded connections can cause dangerous leaks or catastrophic failures.

- Aerospace: Aircraft components require ultra-precise tolerances, given the high-stakes nature of flight safety.

- Automotive: From engine parts to specialized fasteners, accurate threads are crucial for performance and safety in vehicles.

In each of these industries, thread gages serve as the measuring standard to maintain impeccable quality control.

Southwest Calibration Service: Your Local Partner for Excellence

Located in Stafford, Texas, Southwest Calibration Service understands the unique demands of Houston manufacturing quality. We offer:

- Exclusive Master Thread Gages

We have the only master thread gages for API gages (both 7A and 5B calibrations), setting us apart as the go-to provider for specialized oilfield calibration services. Our master gages guarantee the highest level of accuracy available, which is especially critical for oil and gas applications. - Decades of Expertise

Our team comprises seasoned professionals who have worked across diverse industries. We bring a wealth of hands-on knowledge to every project, ensuring you receive the best possible solutions. - ISO/IEC 17025 ANAB Accreditation

We are proud to be ISO/IEC 17025 ANAB accredited, a recognized standard that demonstrates our technical competence and consistent ability to generate valid, precise calibration results. - Fast Turnaround & On-Site Services

We value your time. Our efficient calibration processes and on-site services reduce disruptions to your operations and get you back to full productivity faster. You can regularly expect a 10 business day turnaround time and we also offer expediated times as fast as a 2 day turnaround time (upcharges apply). - Quality Assurance & Certification

Each calibration is backed by detailed documentation and certificates that meet or exceed industry standards. You can move forward with confidence knowing your equipment is calibrated to the highest standards of precision.

Regular thread gage calibration is not just an industry best practice—it’s a critical component for Houston manufacturing quality. The risks of ignoring calibration are too high: product failures, costly rework, potential legal issues, and a tarnished reputation. With Southwest Calibration Service in Stafford, Texas, you gain a partner committed to accurate threading, swift turnaround times, and the most advanced equipment on the market—backed by our ISO/IEC 17025 ANAB accreditation.

Contact us today to request a quote and ensure your thread gages are always performing at their best.